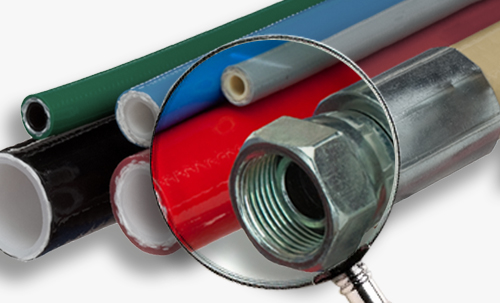

HTR-FG Polyester tubing

TECHNICAL FEATURES

|

|

|

|

|

|

|

|

|

| Code | mm | mm | mm | bar | mm | g/m |

Available Colors |

m |

|

HTR42*AL |

2 |

4 |

1 |

36 |

16 |

11.5 |

T-N-A |

100 |

|

HTR43*AL |

3 |

4 |

0.5 |

13 |

35 |

6.7 |

T-N-A |

100 |

|

HTR53*AL |

3 |

5 |

1 |

27 |

25 |

15.3 |

T-N-A |

100 |

|

HTR63*AL |

3 |

6 |

1.5 |

33 |

30 |

25.9 |

T-N-A |

100 |

|

HTR64*AL |

4 |

6 |

1 |

22 |

30 |

19.2 |

T-N-A |

100 |

|

HTR84*AL |

4 |

8 |

2 |

32 |

35 |

46.0 |

T-N-A |

100 |

|

HTR85*AL |

5 |

8 |

1.5 |

23 |

40 |

37.4 |

T-N-A |

100 |

|

HTR86*AL |

6 |

8 |

1 |

17 |

50 |

26.8 |

T-N-A |

100 |

|

HTR107*AL |

7 |

10 |

1.5 |

19 |

55 |

48.8 |

T-N-A |

50 |

|

HTR1075*AL |

7.5 |

10 |

1.25 |

15 |

60 |

41.9 |

T-N-A |

50 |

|

HTR108*AL |

8 |

10 |

1 |

13 |

70 |

34.5 |

T-N-A |

50 |

|

HTR1284*AL |

8.4 |

12 |

1.8 |

17 |

70 |

70.3 |

T-N-A |

50 |

|

HTR129*AL |

9 |

12 |

1.5 |

16 |

80 |

60.3 |

T-N-A |

50 |

|

HTR1210*AL |

10 |

12 |

1 |

11 |

110 |

42.1 |

T-N-A |

50 |

|

HTR1412*AL |

12 |

14 |

1 |

10 |

115 |

49.8 |

T-N-A |

50 |

|

HTR1512*AL |

12 |

15 |

1.5 |

14 |

120 |

77.6 |

T-N-A |

50 |

|

HTR15125*AL |

12.5 |

15 |

1.25 |

11 |

185 |

65.8 |

T-N-A |

50 |

|

HTR1612*AL |

12 |

16 |

2 |

16 |

190 |

107.3 |

T-N-A |

50 |

|

HTR1814*AL |

14 |

18 |

2 |

12 |

220 |

122.6 |

T-N-A |

50 |

|

HTR2218*AL |

18 |

22 |

2 |

12 |

280 |

153.2 |

T-N-A |

50 |

TECHNICAL FEATURES

Features:

ZEC HTR-FG tubing are suitable for all uses in the food processing industry where high reliability, good mechanical strength and reduced bend radius are required. The use of a special Thermoplastic Polyester Elastomer (TPE or TEEE) allows the achieving of an excellent compromise between flexibility and pressure resistance.

Unlike traditional tubing made of thermoplastic material available on the market, HTR-FG tubing do not contain plasticizers because flexibility is ensured by their natural inner elastomeric molecular structure. Since plasticizer is not released in these tubing, they do not stiffen and there is no food contamination.

Black tubing are recommended for outdoor applications. Tube not suitable for use with chlorinated water.

Working temperature:

from -40°C to +100°C.

Max. working temperature of water-based fluids +50°C.

Specifications:

Reg. EU 1935/2004 and Reg. EU 10/2001. Simulants A, B, C and D1. Standardised testing conditions OM4. Do not use in contact with fatty food.

FDA 21 CFR 177.2600. To use with all type of food up to 65°C and containing less than 8% alcohol.

Italian D.M. 174 of 06/04/2004 for use in drinking water supply chain.

It is end user responsibility to check the updated Declaration of Conformity on the reserved area.

NB: There is an * in the code. This should be replaced with the color code of the tubing.

BURST PRESSURE CORRECTION FACTOR ACCORDING TO TEMPERATURE

POLYESTER TECHNICAL FEATURES

|

General properties |

Standard |

U.M. |

POLYESTER Typical values |

|

Density |

DIN 53479 |

g/cm3 |

1,22 |

|

Hardness |

DIN 53505 |

Shore A Shore D |

--- 63 |

|

Tensile stress at break |

DIN 53504 |

MPa |

41 |

|

Elongation at break |

DIN 53504 |

% |

420 |

|

Charpy impact - unnotched 23°C - unnotched -30°C |

ISO 179 |

kj/m2 |

--- 18 |

|

Abrasion resistance |

DIN 53516 |

mm3 |

--- |

OPTIONAL

For any further information about the optional items, please contact the sales office (sales@zecspa.com)

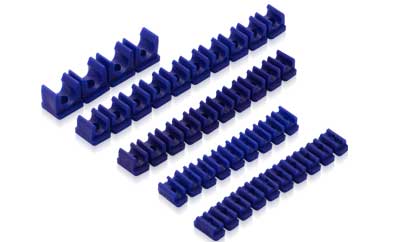

ACCESSORIES

|

Article code |

Ø Tube |

A |

B |

C (mm) |

D |

Ø (mm) |

Positions No. |

|

SFT4 |

4 |

9 |

114 |

11,7 | 8 | 2,8 | 10 |

|

SFT6 |

6 |

9 |

114 |

11,7 | 10 | 2,8 | 10 |

|

SFT8 |

8 |

12 |

143 |

14,6 | 12 | 3,8 | 10 |

|

SFT10 |

10 |

15 |

172 |

17,4 | 13,8 | 5,3 | 10 |

|

SFT12 |

12 |

19 |

162 |

20,5 | 16,8 | 5,3 | 8 |

|

SFT14 |

14 |

21 |

180 |

22,5 | 18,8 | 5,3 | 4 |

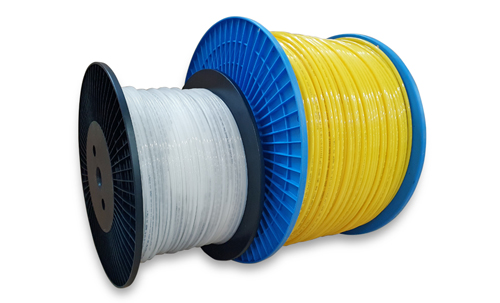

| Codice Bobina Reel Code |

Esterno Outside Ø O |

Interno Inside Ø I |

Foro Hole Ø H |

Lunghezza Length L |

Larghezza Width W |

Tara Tare |

|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | Kg | |

| IBP400200200 | 400 | 200 | 32 | 230 | 200 | 1.8 |

| IBP500250295 | 500 | 250 | 41 |

325 |

295 | 3.1 |

| IBP600310400 | 600 | 310 | 82 | 440 | 400 | 6.0 |

| Code | Dimensions | Tare | ||||

|

Outside Ø |

Inside Ø | Hole Ø | Width |

Length |

||

|

IBP270120200 |

275 mm |

125 mm | 32 mm | 200 mm | 212 mm | 0.5 kg |

| Code | Dimensions | Tare | ||||

|

Outside Ø |

Inside Ø | Hole Ø | Width |

Length |

||

|

IBL500160200 |

500 mm |

160 mm | 80 mm | 200 mm | 220 mm | 1.6 kg |

| IBL500160300 | 500 mm | 160 mm | 80 mm | 300 mm | 320 mm | 2.5 Kg |

| IBL630315335 | 630 mm | 315 mm | 80 mm | 335 mm | 403 mm | 13 Kg |

| IBL700400470 | 700 mm | 400 mm | 80 mm | 470 mm | 500 mm | 12 Kg |

| IBL800400470 | 800 mm | 400 mm | 80 mm | 470 mm | 538 mm | 23 Kg |

| IBLDIN1000 | 1000 mm | 500 mm | 80 mm | 580 mm | 668 mm | 37 Kg |

| IBLDIN1200 | 1200 mm | 600 mm | 82 mm | 610 mm | 644 mm | 32 Kg |

| IBLDIN1400 | 1400 mm | 710 mm | 82 mm | 750 mm | 858 mm | 103 Kg |

| IBLDIN1600 | 1600 mm | 710 mm | 82 mm | 900 mm | 1028 mm | 225 Kg |

| Code | Dimensions | Tare | ||||

|

Outside Ø |

Inside Ø | Hole Ø | Width |

Length |

||

|

IBC470250300 |

470 mm |

250 mm | 40 mm | 300 mm | 330 mm | 0.4 kg |

| IBC550400400 | 550 mm | 400 mm | 60 mm | 400 mm | 430 mm | 1.7 Kg |

| IBC550400500 | 550 mm | 400 mm | 60 mm | 500 mm | 530 mm | 2 Kg |

| IBC600400400 | 600 mm | 400 mm | 60 mm | 400 mm | 430 mm | 1.9 Kg |

| IBC600400500 | 600 mm | 400 mm | 60 mm | 500 mm | 530 mm | 2.1 Kg |

| IBC800400400 | 800 mm | 400 mm | 60 mm | 400 mm | 430 mm | 3.3 Kg |

| IBC1060600320 | 1060 mm | 600 mm | 84 mm | 320 mm | 350 mm | 5.2 Kg |

| IBC1060600500 | 1060 mm | 600 mm | 84 mm | 500 mm | 530 mm | 6 Kg |

.jpg)