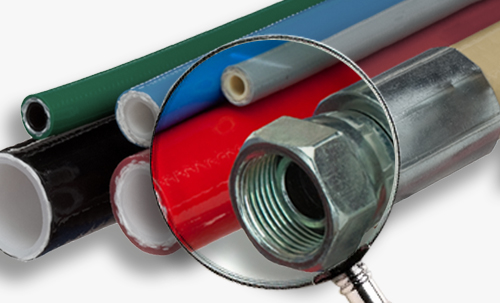

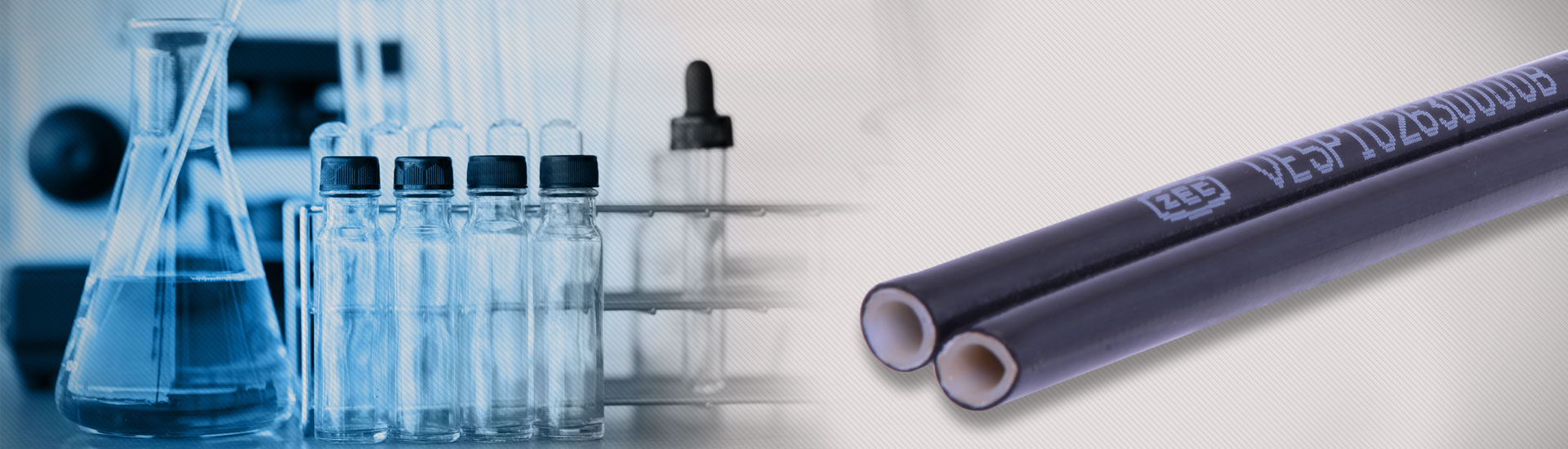

Conductive MT1 Series Thermoplastic hose - Oil-proof Cover*

TECHNICAL FEATURES

|

|

|

|

|

|

|

|||

|

Code |

inch |

mm |

DN |

mm |

bar |

bar |

mm |

g/m |

Ferrule Code (*) |

|

MT110000 |

1/8" |

3.5 |

3 |

7.5 |

375 |

500 |

30 |

76 |

BP18MT1 |

|

MT120000 |

3/16" |

4.8 |

5 |

10.0 |

350 |

467 |

30 |

131 |

BP316MT1 |

|

MT130000 |

1/4" |

6.4 |

6 |

11.9 |

300 |

400 |

40 |

165 |

BP14MT1 |

|

MT140000 |

5/16" |

8.0 |

8 |

14.0 |

240 |

320 |

50 |

205 |

BP516R7V |

|

MT150000 |

3/8" |

9.7 |

10 |

16.0 |

225 |

300 |

60 |

253 |

BP38R1TV |

|

MT160000 |

1/2" |

13.0 |

12 |

19.2 |

190 |

254 |

75 |

314 |

BP12R2TV |

|

MT170000 |

5/8" |

16.3 |

16 |

23.3 |

150 |

200 |

110 |

406 |

BP58R7V |

|

MT180000 |

3/4" |

19.2 |

19 |

25.5 |

130 |

174 |

150 |

447 |

BP34R7V |

|

MT190000 |

1" |

25.7 |

25 |

32.5 |

105 |

140 |

185 |

590 |

BP1R7V |

|

MT1100000 |

1"1/4 |

32.0 |

32 |

40.0 |

70 |

94 |

290 |

842 |

BP114JC7 |

(*) Possibilità di boccole in acciaio inox / Stainless steel ferrules available

|

|

|

|

|

|

|

|||

|

Code |

inch |

-dash |

mm |

inch |

psi |

psi |

inch |

lbs/ft |

Ferrule Code (*) |

|

MT110000 |

1/8" |

-2 |

3.5 |

0.295 |

5437 |

7250 |

1.18 |

0.051 |

BP18MT1 |

|

MT120000 |

3/16" |

-3 |

4.8 |

0.394 |

5075 |

6772 |

1.18 |

0.088 |

BP316MT1 |

|

MT130000 |

1/4" |

-4 |

6.4 |

0.469 |

4350 |

5800 |

1.57 |

0.111 |

BP14MT1 |

|

MT140000 |

5/16" |

-5 |

8.0 |

0.551 |

3480 |

4640 |

1.97 |

0.138 |

BP516R7V |

|

MT150000 |

3/8" |

-6 |

9.7 |

0.630 |

3262 |

4350 |

2.36 |

0.170 |

BP38R1TV |

|

MT160000 |

1/2" |

-8 |

13.0 |

0.756 |

2755 |

3683 |

2.95 |

0.211 |

BP12R2TV |

|

MT170000 |

5/8" |

-10 |

16.3 |

0.917 |

2175 |

2900 |

4.33 |

0.273 |

BP58R7V |

|

MT180000 |

3/4" |

-12 |

19.2 |

1.003 |

1885 |

2523 |

5.91 |

0.300 |

BP34R7V |

|

MT190000 |

1" |

-16 |

25.7 |

1.280 |

1520 |

2030 |

7.28 |

0.396 |

BP1R7V |

|

MT1100000 |

1"1/4 |

-20 |

32.0 |

1.574 |

1015 |

1360 |

11.41 |

0.566 |

BP114JC7 |

(*) Possibilità di boccole in acciaio inox / Stainless steel ferrules available

TECHNICAL FEATURES

Technical-constructive features:

Inner core in polyamide, reinforcement in high tensile steel braid and exterior covering in antiabrasion polyurethane, micro perforated on request for the conduction of air and compatible gases.

Applications:

hoses of the MT1 series have been created for the high pressure conduction of Polyols, Solvents, Paints and compatible gases.

Working temperature:

from –40°C to +100°C from -40°F to +212°F.

Max. working temperature of air, water and water-based fluids is + 70°C (+158°F).

Working pressure:

Safety ratio 1:4 for Dynamic Pressure

Safety ratio 1:3 for Static Pressure

Vacuum rating:

0.93 bar; 700 mm Hg

Specifications:

Hoses meet or exceed pressures under SAE 100R1 - EN 853 1st, 1SN - EN 857 1SC Standards.

*The oil-proof feature of the cover means that the hose is resistant to prolonged contact with oils and lubricants

ACCESSORIES

|

TECHNICAL DATA |

Code PMZ47 |

Code PPZ47 |

|

Crimping force |

100 TON (110 US TONS) |

100 TON (110 US TONS) |

|

Capacity |

1" |

1" |

|

Ø Maximum Crimping |

46 mm * (1.811") |

46 mm * (1.811") |

|

Die Opening |

Ø + 20 mm (Ø + 0.788") |

Ø + 20 mm (Ø + 0.788") |

|

90° Fittings |

3/8" |

3/8" |

| DIMENSIONS LxWxH | 390x510x300 mm (15.3"x20.7"x11.8") |

380x430x400 mm (14.9"x16.9"x15.7") |

|

Weight |

32 kg (71 Lbs) |

38 kg (84 Lbs) |

|

Required effort on the lever |

30 kg (66 Lbs) |

--- |

| Pneumatic Input | --- | Max. 7 bar (100 psi) |

|

Cylinder |

Single Acting |

Singel acting |

|

INCLUDED ACCESSORIES |

|

Die holder drawer |

|

2.5 LT OIL (for pneumatic press) |

|

DIES |

PMZ47 - PPZ47 | ||||||||

| Part nr. MPRESS- | APPZ4710 | APPZ4712 | APPZ4714 | APPZ4716 | APPZ4719 | APPZ4722 | APPZ4725 | APPZ4729 | APPZ4739 |

|

Die Set Diameter |

10 | 12 | 14 | 16 | 19 | 22 | 25 | 29 | 39* |

|

Die Length |

55 | 55 | 55 | 55 | 55 | 55 | 65 | 65 | 64 |

* Die Holder

|

OPTIONAL |

|

|

Special DIES (diameter 6) |

Tool for die change |

|

Part. n: MPRESSAPPZ476 |

Part. n: MPZ47UCM |

|

Chemical Resistance |

|

|

Acid, Diluite |

Good |

|

Acid, Concentrated |

Poor to Fail |

|

Acid, Organic (diluite) |

Good |

|

Acid, Organic (concentrated) |

Poor |

|

Acid, Inorganic |

Fair to Good |

|

Alcohol’s |

Fair to Good |

|

Aldehydes |

Poor to fail |

|

Alkalies, Diluite |

Good |

|

Alkalies, Concentrated |

Poor to Good |

|

Amines |

Poor |

|

Animal & Vegetable Oils |

Good to Excellent |

|

Brake Fluids, Non-Petroleum Based |

Poor |

|

Diester Oils |

Fair to |

|

Esters, Alkyl Phosphate |

Poor |

|

Esters, Aryl Phosphate |

Poor to Fair |

|

Ethers |

Poor |

|

Fuel, Aliphatic Hydrocarbon |

Good to Excellent |

|

Fuel, Aromatic Hydrocarbon |

Fair to Good |

|

Fuel, Extended (Oxygenated) |

Fair to Good |

|

Halogenated Solvents |

Poor |

|

Hydrocarbon, Halogenated |

Poor to Fair |

|

Ketones |

Poor |

|

Lacquer Solvents |

Fair |

|

LP Gases & Fuel Oils |

Excellent |

|

Minelal Oils |

Excellent |

|

Oil Resistant |

Good to Excellent |

|

Petroleum Aromatic |

Good |

|

Petroleum Non-Aromatic |

Excellent |

|

Refrigerant Ammonia |

Good |

|

Silicone Oil |

Good |

|

Solvent Resistant |

Good to Excellent |

|

|

|

|

Thermal Properties |

|

|

Low Temperature Range |

- 55°C to - 15°C |

|

Minimun for Continuous Use (static) |

- 40°C |

|

Brittle Point |

- 55°C to - 15°C |

|

High Temperature Range |

+ 100°C to + 125°C |

|

Maximum for Continuous Use (static) |

+ 125°C |

|

|

|

|

Environmental Performance |

|

|

Colorability |

Excellent |

|

Flame Resistance |

Poor |

|

Gas Permeability |

Fair to Excellent |

|

Odor |

Good |

|

Ozone Resistance |

Fair to Good |

|

Oxidation Resistance |

Good |

|

Radioation Resistance |

Fair to Good |

|

Steam Resistance |

Fair to Good |

|

Sunlight Resistance |

Poor to Good |

|

Taste Retention |

Fair to Good |

|

Weather Resistance |

Fair to Good |

|

Water Resistance |

Good to Excellent |

|

Article Code

|

Internal Diameter (mm) |

Outside Diameter (mm) |

Wall Thickness (mm) |

Strip Width (mm) |

Weight (g/m) |

Hose Diameter Range (mm) |

Length (m) |

|

GS0907 |

7 |

9 |

1.0 |

6.5 |

22 |

8÷10 |

150 |

|

GS128 |

9.5 |

12 |

1.7 |

10 |

46 |

10÷17 |

50 |

|

GS1612 |

12.5 |

16 |

1.8 |

12 |

76 |

13÷22 |

50 |

|

GS2016 |

16 |

20 |

1.8 |

14.5 |

86 |

16÷27 |

50 |

|

GS2520 |

21 |

25 |

2 |

21 |

112 |

21÷35 |

50 |

|

GS3227 |

27 |

32 |

2 |

24 |

177 |

27÷44 |

50 |

|

GS4036 |

34 |

40 |

2.5 |

30 |

217 |

34÷55 |

50 |

|

GS5044 |

44 |

50 |

3 |

35 |

278 |

44÷70 |

50 |

|

GS6356 |

55 |

63 |

3.5 |

40 |

588 |

55÷87 |

20 |

|

GS7567 |

66 |

75 |

3.4 |

40 |

813 |

67÷103 |

20 |

|

GS9080 |

79 |

90 |

5 |

45 |

1033 |

80÷122 |

20 |

|

GS110100 |

99 |

110 |

5.5 |

55 |

1200 |

100÷152 |

12 |

|

GS125114 |

114 | 125 | 5.6 | 55 | 1638 | 115÷174 | 12 |

|

GS140129 |

129 | 140 | 5.6 | 55 | 1807 | 130÷196 | 8 |

|

GS160148 |

148 | 160 | 6 | 60 | 2031 | 150÷224 | 6 |

|

Article code |

Width (mm) |

Ø (mm) |

Weight (g/m) |

Lenght (mt) |

|

GT35* |

35 |

20 |

27 |

100 |

|

GT40* |

40 |

22 |

32 |

100 |

|

GT45* |

45 |

25 |

34 |

100 |

|

GT50* |

50 |

28 |

38 |

100 |

|

GT55* |

55 |

32 |

42 |

100 |

|

GT60* |

60 |

35 |

45 |

100 |

|

GT65* |

65 |

38 |

48 |

100 |

|

GT80* |

80 |

45 |

60 |

100 |

|

GT90* |

90 |

50 |

65 |

100 |

|

GT120* |

120 |

70 |

96 |

100 |

|

GT150* |

150 |

90 |

112 |

100 |

|

Ferrule Code |

Dimensions (mm) |

||

| d | D | L | |

| BPL1922 | 19 | 22 | 25 |

| BPL2225 | 22 | 25 | 30 |

| BPL2528 | 25 | 28 | 30 |

| BPL2730 | 27 | 30 | 33 |

| BPL2932 | 29 | 32 | 34 |

| BPL3235 | 32 | 35 | 36 |

| BPL3538 | 35 | 38 | 36 |

| BPL3740 | 37 | 40 | 38 |

| BPL3942 | 39 | 42 | 40 |

| BPL4245 | 42 | 45 | 42 |

| BPL4650 | 46 | 50 | 45 |

| BPL5155 | 51 | 55 | 48 |

| BPL5660 | 56 | 60 | 50 |

| BPL6670 | 66 | 70 | 54 |

| BPL7783 | 77 | 83 | 64 |

|

ZEC GT Textile Sleeves are particularly suitable for hydraulic and pneumatic applications, containing single and multiple tubings/hoses.

|

|

|

|

|

GT Textile Sleeves have obtained the approval from the Mine Safety and Health Administration by the U.S. Department of Labor with marking "MSHA IC332-08".

|

Article code |

Ø Inside (mm) |

Silicone thickness (Min.) (mm) |

Rolls Length (m) |

|

GFVS12 |

12 |

1 |

20 |

|

GFVS15 |

15 |

1 |

20 |

|

GFVS20 |

20 |

1 |

20 |

|

GFVS25 |

25 |

1 |

20 |

|

GFVS30 |

30 |

1 |

20 |

|

GFVS38 |

38 |

1 |

20 |

|

GFVS40 |

40 |

1 |

20 |

|

GFVS45 |

45 |

1 |

15 |

|

GFVS50 |

50 |

1 |

15 |

|

GFVS60 |

60 |

1 |

15 |

|

GFVS65 |

65 |

1 |

15 |

|

Article code |

Ø Inside (mm) |

Thickness (mm) |

Weight (g/m) |

Reels (m) |

|

|

normal |

thickness |

||||

|

GPVC10 |

- - - |

10 |

0,5 |

26 |

125 |

|

GPVC16 |

- - - |

16 |

0,5 |

39 |

100 |

|

GPVC18 |

- - - |

18 |

0,5 |

52 |

100 |

|

GPVC20 |

- - - |

20 |

0,6 |

58 |

100 |

|

- - - |

GPVCS20 |

20 |

1,5 |

122,5 |

100 |

|

GPVC22 |

- - - |

22 |

0,6 |

63 |

100 |

|

- - - |

GPVCS23 |

23 |

1,5 |

140 |

100 |

|

GPVC25 |

- - - |

25 |

0,6 |

72 |

100 |

|

- - - |

GPVCS25 |

25 |

1,5 |

151 |

100 |

|

- - - |

GPVCS27 |

27 |

1,5 |

164 |

100 |

|

GPVC28 |

- - - |

28 |

0,6 |

82 |

100 |

|

GPVC30 |

- - - |

30 |

0,6 |

87 |

100 |

|

- - - |

GPVCS30 |

30 |

1,5 |

180 |

100 |

|

- - - |

GPVCS32 |

32 |

1,5 |

191 |

50 |

|

GPVC33 |

- - - |

33 |

0,7 |

104 |

50 |

|

- - - |

GPVCS33 |

33 |

1,5 |

197 |

50 |

|

GPVC38 |

- - - |

38 |

0,7 |

135 |

50 |

|

- - - |

GPVCS38 |

38 |

1,5 |

225 |

50 |

|

GPVC40 |

- - - |

40 |

0,7 |

141 |

50 |

|

- - - |

GPVCS40 |

40 |

1,5 |

241 |

50 |

|

GPVC45 |

- - - |

45 |

0,7 |

144 |

50 |

|

- - - |

GPVCS48 |

48 |

1,5 |

282 |

50 |

|

GPVC50 |

- - - |

50 |

0,7 |

167 |

50 |

|

GPVC55 |

- - - |

55 |

0,7 |

184 |

50 |

| Code |

A |

B mm |

C mm |

| HBR8 | 8.5 | 10.4 | 120 |

| HBR10 | 13.2 | 16.0 | 151 |

| HBR20 | 15.6 | 17.7 | 134 |

| HBR40 | 17.0 | 19.2 | 146 |

| HBR60 | 19.0 | 21.6 | 163 |

| HBR80 | 20.7 | 23.5 | 177 |

| HBR100 | 22.1 | 25.3 | 197 |

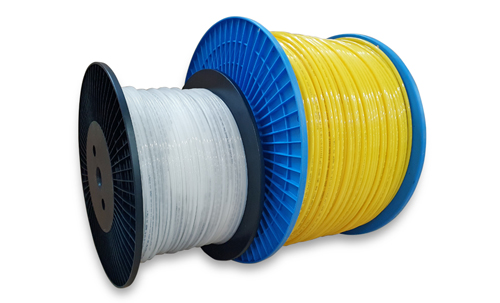

| Codice Bobina Reel Code |

Esterno Outside Ø O |

Interno Inside Ø I |

Foro Hole Ø H |

Lunghezza Length L |

Larghezza Width W |

Tara Tare |

|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | Kg | |

| IBP400200200 | 400 | 200 | 32 | 230 | 200 | 1.8 |

| IBP500250295 | 500 | 250 | 41 |

325 |

295 | 3.1 |

| IBP600310400 | 600 | 310 | 82 | 440 | 400 | 6.0 |

| Code | Dimensions | Tare | ||||

|

Outside Ø |

Inside Ø | Hole Ø | Width |

Length |

||

|

IBP270120200 |

275 mm |

125 mm | 32 mm | 200 mm | 212 mm | 0.5 kg |

| Code | Dimensions | Tare | ||||

|

Outside Ø |

Inside Ø | Hole Ø | Width |

Length |

||

|

IBL500160200 |

500 mm |

160 mm | 80 mm | 200 mm | 220 mm | 1.6 kg |

| IBL500160300 | 500 mm | 160 mm | 80 mm | 300 mm | 320 mm | 2.5 Kg |

| IBL630315335 | 630 mm | 315 mm | 80 mm | 335 mm | 403 mm | 13 Kg |

| IBL700400470 | 700 mm | 400 mm | 80 mm | 470 mm | 500 mm | 12 Kg |

| IBL800400470 | 800 mm | 400 mm | 80 mm | 470 mm | 538 mm | 23 Kg |

| IBLDIN1000 | 1000 mm | 500 mm | 80 mm | 580 mm | 668 mm | 37 Kg |

| IBLDIN1200 | 1200 mm | 600 mm | 82 mm | 610 mm | 644 mm | 32 Kg |

| IBLDIN1400 | 1400 mm | 710 mm | 82 mm | 750 mm | 858 mm | 103 Kg |

| IBLDIN1600 | 1600 mm | 710 mm | 82 mm | 900 mm | 1028 mm | 225 Kg |

| Code | Dimensions | Tare | ||||

|

Outside Ø |

Inside Ø | Hole Ø | Width |

Length |

||

|

IBC470250300 |

470 mm |

250 mm | 40 mm | 300 mm | 330 mm | 0.4 kg |

| IBC550400400 | 550 mm | 400 mm | 60 mm | 400 mm | 430 mm | 1.7 Kg |

| IBC550400500 | 550 mm | 400 mm | 60 mm | 500 mm | 530 mm | 2 Kg |

| IBC600400400 | 600 mm | 400 mm | 60 mm | 400 mm | 430 mm | 1.9 Kg |

| IBC600400500 | 600 mm | 400 mm | 60 mm | 500 mm | 530 mm | 2.1 Kg |

| IBC800400400 | 800 mm | 400 mm | 60 mm | 400 mm | 430 mm | 3.3 Kg |

| IBC1060600320 | 1060 mm | 600 mm | 84 mm | 320 mm | 350 mm | 5.2 Kg |

| IBC1060600500 | 1060 mm | 600 mm | 84 mm | 500 mm | 530 mm | 6 Kg |