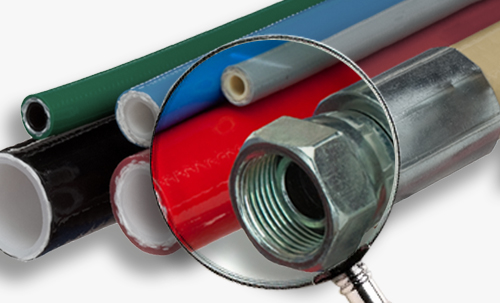

AT7-PE Series Thermoplastic hose - Water proof Cover*

TECHNICAL FEATURES

|

|

|

|

|

|

|||

|

Code |

inch |

mm |

DN |

mm |

bar |

mm |

g/m |

Ferrule Code (*) |

|

AT737100PE |

1/4" |

6.4 |

6 |

11.8 |

200 |

35 |

84 |

BP14R7 |

|

AT757100PE |

3/8" |

9.7 |

10 |

16 |

175 |

55 |

144 |

BP38R7V |

|

AT767100PE |

1/2" |

13 |

12 |

20.3 |

140 |

75 |

200 |

BP12R7V |

|

AT787100PE |

3/4" |

19.2 |

19 |

26.5 |

90 |

145 |

294 |

BP34R7 |

(*) Possibilità di boccole in acciaio inox / Stainless steel ferrules available

|

|

|

|

|

|

|||

|

Code |

inch |

-dash |

mm |

inch |

psi |

inch |

lbs/ft |

Ferrule Code (*) |

|

AT737100PE |

1/4" |

-4 |

6.4 |

0.465 |

2900 |

1.38 |

0.056 |

BP14R7 |

|

AT757100PE |

3/8" |

-6 |

9.7 |

0.630 |

2537 |

2.17 |

0.097 |

BP38R7V |

|

AT767100PE |

1/2" |

-8 |

13 |

0.799 |

2030 |

2.95 |

0.135 |

BP12R7V |

|

AT787100PE |

3/4" |

-12 |

19.2 |

1.043 |

1305 |

5.71 |

0.198 |

BP34R7 |

(*) Possibilità di boccole in acciaio inox / Stainless steel ferrules available

TECHNICAL FEATURES

Technical-constructive features:

Inner core in polyethylene, polyester textile reinforcement and exterior covering in antiabrasion polyurethane stabilized against UV rays and resistant to hydrolysis and microorganisms, micro perforated for air and compatible gases.

Applications:

AT7-PE hose series have been created for the medium pressure conduction of foodstuff, suitable for outdoor applications in MARINE environments having a high percentage of humidity.

Working temperature:

From -20°C to +40°C (from -4°F to +104°F)

Working pressure:

Safety ratio 1:4

Vacuum rating:

0.93 bar; 700 mm Hg

Specifications:

Reg. EU 1935/2004, Reg. EU 10/2011. Simulants A, B and D2. Standardised testing conditions OM2.

FDA 21 CFR 177.1520

Italian DM 174 of 06/04/2004 for use in drinking water supply.

It is end user responsibility to check the updated Declaration of Conformity on the reserved area.

*The water-proof feature of the cover means that the hose is especially suitable for wet and saline environments where there are extreme temperature changes.

OPTIONAL

For any further information about the optional items, please contact the sales office (sales@zecspa.com)

ACCESSORIES

|

TECHNICAL DATA |

Code PMZ47 |

Code PPZ47 |

|

Crimping force |

100 TON (110 US TONS) |

100 TON (110 US TONS) |

|

Capacity |

1" |

1" |

|

Ø Maximum Crimping |

46 mm * (1.811") |

46 mm * (1.811") |

|

Die Opening |

Ø + 20 mm (Ø + 0.788") |

Ø + 20 mm (Ø + 0.788") |

|

90° Fittings |

3/8" |

3/8" |

| DIMENSIONS LxWxH | 390x510x300 mm (15.3"x20.7"x11.8") |

380x430x400 mm (14.9"x16.9"x15.7") |

|

Weight |

32 kg (71 Lbs) |

38 kg (84 Lbs) |

|

Required effort on the lever |

30 kg (66 Lbs) |

--- |

| Pneumatic Input | --- | Max. 7 bar (100 psi) |

|

Cylinder |

Single Acting |

Singel acting |

|

INCLUDED ACCESSORIES |

|

Die holder drawer |

|

2.5 LT OIL (for pneumatic press) |

|

DIES |

PMZ47 - PPZ47 | ||||||||

| Part nr. MPRESS- | APPZ4710 | APPZ4712 | APPZ4714 | APPZ4716 | APPZ4719 | APPZ4722 | APPZ4725 | APPZ4729 | APPZ4739 |

|

Die Set Diameter |

10 | 12 | 14 | 16 | 19 | 22 | 25 | 29 | 39* |

|

Die Length |

55 | 55 | 55 | 55 | 55 | 55 | 65 | 65 | 64 |

* Die Holder

|

OPTIONAL |

|

|

Special DIES (diameter 6) |

Tool for die change |

|

Part. n: MPRESSAPPZ476 |

Part. n: MPZ47UCM |

|

Chemical Resistance |

|

|

Acid, Diluite |

Good |

|

Acid, Concentrated |

Poor to Fail |

|

Acid, Organic (diluite) |

Good |

|

Acid, Organic (concentrated) |

Poor |

|

Acid, Inorganic |

Fair to Good |

|

Alcohol’s |

Fair to Good |

|

Aldehydes |

Poor to fail |

|

Alkalies, Diluite |

Good |

|

Alkalies, Concentrated |

Poor to Good |

|

Amines |

Poor |

|

Animal & Vegetable Oils |

Good to Excellent |

|

Brake Fluids, Non-Petroleum Based |

Poor |

|

Diester Oils |

Fair to |

|

Esters, Alkyl Phosphate |

Poor |

|

Esters, Aryl Phosphate |

Poor to Fair |

|

Ethers |

Poor |

|

Fuel, Aliphatic Hydrocarbon |

Good to Excellent |

|

Fuel, Aromatic Hydrocarbon |

Fair to Good |

|

Fuel, Extended (Oxygenated) |

Fair to Good |

|

Halogenated Solvents |

Poor |

|

Hydrocarbon, Halogenated |

Poor to Fair |

|

Ketones |

Poor |

|

Lacquer Solvents |

Fair |

|

LP Gases & Fuel Oils |

Excellent |

|

Minelal Oils |

Excellent |

|

Oil Resistant |

Good to Excellent |

|

Petroleum Aromatic |

Good |

|

Petroleum Non-Aromatic |

Excellent |

|

Refrigerant Ammonia |

Good |

|

Silicone Oil |

Good |

|

Solvent Resistant |

Good to Excellent |

|

|

|

|

Thermal Properties |

|

|

Low Temperature Range |

- 55°C to - 15°C |

|

Minimun for Continuous Use (static) |

- 40°C |

|

Brittle Point |

- 55°C to - 15°C |

|

High Temperature Range |

+ 100°C to + 125°C |

|

Maximum for Continuous Use (static) |

+ 125°C |

|

|

|

|

Environmental Performance |

|

|

Colorability |

Excellent |

|

Flame Resistance |

Poor |

|

Gas Permeability |

Fair to Excellent |

|

Odor |

Good |

|

Ozone Resistance |

Fair to Good |

|

Oxidation Resistance |

Good |

|

Radioation Resistance |

Fair to Good |

|

Steam Resistance |

Fair to Good |

|

Sunlight Resistance |

Poor to Good |

|

Taste Retention |

Fair to Good |

|

Weather Resistance |

Fair to Good |

|

Water Resistance |

Good to Excellent |

|

Article Code

|

Internal Diameter (mm) |

Outside Diameter (mm) |

Wall Thickness (mm) |

Strip Width (mm) |

Weight (g/m) |

Hose Diameter Range (mm) |

Length (m) |

|

GS0907 |

7 |

9 |

1.0 |

6.5 |

22 |

8÷10 |

150 |

|

GS128 |

9.5 |

12 |

1.7 |

10 |

46 |

10÷17 |

50 |

|

GS1612 |

12.5 |

16 |

1.8 |

12 |

76 |

13÷22 |

50 |

|

GS2016 |

16 |

20 |

1.8 |

14.5 |

86 |

16÷27 |

50 |

|

GS2520 |

21 |

25 |

2 |

21 |

112 |

21÷35 |

50 |

|

GS3227 |

27 |

32 |

2 |

24 |

177 |

27÷44 |

50 |

|

GS4036 |

34 |

40 |

2.5 |

30 |

217 |

34÷55 |

50 |

|

GS5044 |

44 |

50 |

3 |

35 |

278 |

44÷70 |

50 |

|

GS6356 |

55 |

63 |

3.5 |

40 |

588 |

55÷87 |

20 |

|

GS7567 |

66 |

75 |

3.4 |

40 |

813 |

67÷103 |

20 |

|

GS9080 |

79 |

90 |

5 |

45 |

1033 |

80÷122 |

20 |

|

GS110100 |

99 |

110 |

5.5 |

55 |

1200 |

100÷152 |

12 |

|

GS125114 |

114 | 125 | 5.6 | 55 | 1638 | 115÷174 | 12 |

|

GS140129 |

129 | 140 | 5.6 | 55 | 1807 | 130÷196 | 8 |

|

GS160148 |

148 | 160 | 6 | 60 | 2031 | 150÷224 | 6 |

|

Article code |

Width (mm) |

Ø (mm) |

Weight (g/m) |

Lenght (mt) |

|

GT35* |

35 |

20 |

27 |

100 |

|

GT40* |

40 |

22 |

32 |

100 |

|

GT45* |

45 |

25 |

34 |

100 |

|

GT50* |

50 |

28 |

38 |

100 |

|

GT55* |

55 |

32 |

42 |

100 |

|

GT60* |

60 |

35 |

45 |

100 |

|

GT65* |

65 |

38 |

48 |

100 |

|

GT80* |

80 |

45 |

60 |

100 |

|

GT90* |

90 |

50 |

65 |

100 |

|

GT120* |

120 |

70 |

96 |

100 |

|

GT150* |

150 |

90 |

112 |

100 |

|

Ferrule Code |

Dimensions (mm) |

||

| d | D | L | |

| BPL1922 | 19 | 22 | 25 |

| BPL2225 | 22 | 25 | 30 |

| BPL2528 | 25 | 28 | 30 |

| BPL2730 | 27 | 30 | 33 |

| BPL2932 | 29 | 32 | 34 |

| BPL3235 | 32 | 35 | 36 |

| BPL3538 | 35 | 38 | 36 |

| BPL3740 | 37 | 40 | 38 |

| BPL3942 | 39 | 42 | 40 |

| BPL4245 | 42 | 45 | 42 |

| BPL4650 | 46 | 50 | 45 |

| BPL5155 | 51 | 55 | 48 |

| BPL5660 | 56 | 60 | 50 |

| BPL6670 | 66 | 70 | 54 |

| BPL7783 | 77 | 83 | 64 |

|

ZEC GT Textile Sleeves are particularly suitable for hydraulic and pneumatic applications, containing single and multiple tubings/hoses.

|

|

|

|

|

GT Textile Sleeves have obtained the approval from the Mine Safety and Health Administration by the U.S. Department of Labor with marking "MSHA IC332-08".

|

Article code |

Ø Inside (mm) |

Silicone thickness (Min.) (mm) |

Rolls Length (m) |

|

GFVS12 |

12 |

1 |

20 |

|

GFVS15 |

15 |

1 |

20 |

|

GFVS20 |

20 |

1 |

20 |

|

GFVS25 |

25 |

1 |

20 |

|

GFVS30 |

30 |

1 |

20 |

|

GFVS38 |

38 |

1 |

20 |

|

GFVS40 |

40 |

1 |

20 |

|

GFVS45 |

45 |

1 |

15 |

|

GFVS50 |

50 |

1 |

15 |

|

GFVS60 |

60 |

1 |

15 |

|

GFVS65 |

65 |

1 |

15 |

|

Article code |

Ø Inside (mm) |

Thickness (mm) |

Weight (g/m) |

Reels (m) |

|

|

normal |

thickness |

||||

|

GPVC10 |

- - - |

10 |

0,5 |

26 |

125 |

|

GPVC16 |

- - - |

16 |

0,5 |

39 |

100 |

|

GPVC18 |

- - - |

18 |

0,5 |

52 |

100 |

|

GPVC20 |

- - - |

20 |

0,6 |

58 |

100 |

|

- - - |

GPVCS20 |

20 |

1,5 |

122,5 |

100 |

|

GPVC22 |

- - - |

22 |

0,6 |

63 |

100 |

|

- - - |

GPVCS23 |

23 |

1,5 |

140 |

100 |

|

GPVC25 |

- - - |

25 |

0,6 |

72 |

100 |

|

- - - |

GPVCS25 |

25 |

1,5 |

151 |

100 |

|

- - - |

GPVCS27 |

27 |

1,5 |

164 |

100 |

|

GPVC28 |

- - - |

28 |

0,6 |

82 |

100 |

|

GPVC30 |

- - - |

30 |

0,6 |

87 |

100 |

|

- - - |

GPVCS30 |

30 |

1,5 |

180 |

100 |

|

- - - |

GPVCS32 |

32 |

1,5 |

191 |

50 |

|

GPVC33 |

- - - |

33 |

0,7 |

104 |

50 |

|

- - - |

GPVCS33 |

33 |

1,5 |

197 |

50 |

|

GPVC38 |

- - - |

38 |

0,7 |

135 |

50 |

|

- - - |

GPVCS38 |

38 |

1,5 |

225 |

50 |

|

GPVC40 |

- - - |

40 |

0,7 |

141 |

50 |

|

- - - |

GPVCS40 |

40 |

1,5 |

241 |

50 |

|

GPVC45 |

- - - |

45 |

0,7 |

144 |

50 |

|

- - - |

GPVCS48 |

48 |

1,5 |

282 |

50 |

|

GPVC50 |

- - - |

50 |

0,7 |

167 |

50 |

|

GPVC55 |

- - - |

55 |

0,7 |

184 |

50 |

| Code |

A |

B mm |

C mm |

| HBR8 | 8.5 | 10.4 | 120 |

| HBR10 | 13.2 | 16.0 | 151 |

| HBR20 | 15.6 | 17.7 | 134 |

| HBR40 | 17.0 | 19.2 | 146 |

| HBR60 | 19.0 | 21.6 | 163 |

| HBR80 | 20.7 | 23.5 | 177 |

| HBR100 | 22.1 | 25.3 | 197 |

.jpg)